Introdução

A fruta da data (Phoenix Dactylifera), um item básico nas culturas do Oriente Médio e do Norte da África por milênios, evoluiu para um superalimento globalmente estimado. À medida que a demanda surge, os produtores enfrentam pressão de montagem para fornecer datas de alta qualidade e classificadas uniformemente com eficiência. Digite a máquina de classificação automatizada de data - uma maravilha tecnológica que transforma a indústria. Este blog explora como essas máquinas funcionam, seus benefícios e seu impacto na agricultura moderna.

O desafio da classificação tradicional de data

Historicamente, a classificação da data baseou -se no trabalho manual: os trabalhadores escolhidos a dedo com base em tamanho, cor, maturação e defeitos. Embora eficaz para pequenos lotes, esse método consome tempo, intensivo em mão-de-obra e propenso a erros humanos. Com a produção de data global superior a 9 milhões de toneladas métricas anualmente (FAO, 2023), a escalabilidade e a precisão tornaram -se pontos críticos.

Como as máquinas de classificação de data funcionam

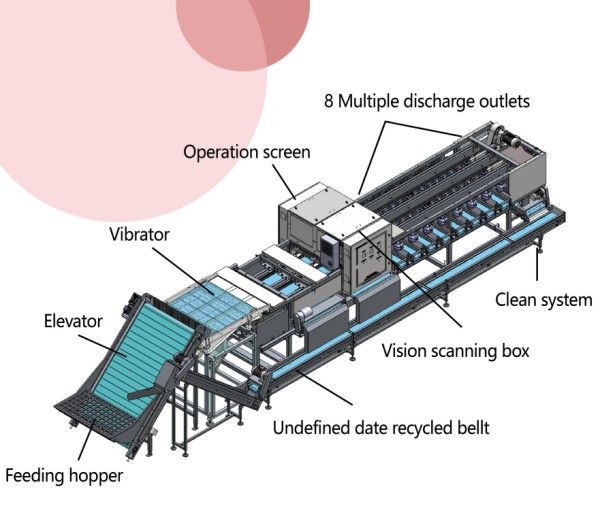

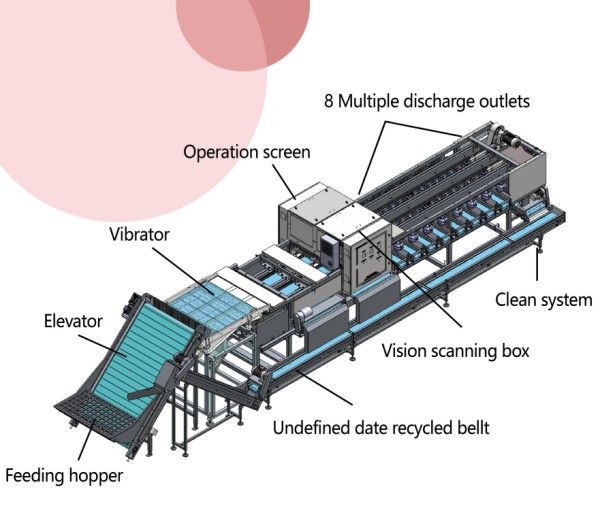

As máquinas de classificação de data modernas integram tecnologias avançadas para otimizar o processo:

Alimentação e distribuição

As datas são carregadas em uma correia transportadora vibratória, garantindo distribuição uniforme para inspeção individual.

Visão computacional e espectroscopia

Câmeras de alta resolução e sensores de infravermelho próximo (NIR) analisam cada frutas:

Tamanho e forma: os scanners a laser medem as dimensões para categorizar as datas (por exemplo, graus de prêmio versus padrão).

Defeitos de cor e superfície: a imagem movida a IA detecta hematomas, rachaduras ou descoloração.

Qualidade interna: os sensores NIR avaliam o teor de umidade, os níveis de açúcar e a maturação sem contato físico.

Sistemas ejetores

As datas defeituosas ou descobertas são removidas rapidamente usando jatos pneumáticos ou braços mecânicos.

Classificação e embalagem

As datas classificadas são canalizadas em caixas com base em critérios predefinidos, prontos para embalagens ou processamento adicional.

Principais vantagens da automação

Velocidade: Processe até 10.000 datas por hora, superando a classificação manual em 500%.

Precisão: os algoritmos de IA atingem> 99% de taxas de detecção de defeitos, minimizando o desperdício.

Eficiência de custos: reduza os custos de mão -de -obra em até 70% ao aumentar a produção.

Consistência: elimine a subjetividade humana, garantindo a qualidade uniforme para os mercados de exportação.

Insights de dados: as análises em tempo real ajudam a otimizar as colheitas e as cadeias de suprimentos.

Estudo de caso: máquina de classificação de data vsee

Resultados incluídos:

Um aumento de 40% no volume de exportação devido ao processamento mais rápido.

Uma redução de 15% nos resíduos de detecção precisa de defeitos.

Tendências futuras

As inovações no horizonte incluem:

Manutenção preditiva orientada pela IA: máquinas que não diagnosticaram problemas mecânicos.

Integração do Blockchain: rastreabilidade de fazenda para consumidor por meio de códigos QR.

Armas de embalagem robótica: sistemas de ponta a ponta totalmente automatizados.

Conclusão

As máquinas automatizadas de classificação de data não são mais um luxo, mas uma necessidade para os produtores que visam competir em um mercado de rápido crescimento e orientado pela qualidade. Ao se casar com a tecnologia de ponta com a tradição agrícola, esses sistemas garantem que cada data-seja destinada a uma prateleira de supermercado ou uma receita gourmet-representa os mais altos padrões de excelência.

À medida que o setor avança, uma coisa é clara: o futuro da agricultura é inteligente, eficiente e inegavelmente automatizado.

CN

CN português

português English

English français

français русский

русский español

español ไทย

ไทย Indonesia

Indonesia Tiếng việt

Tiếng việt العربية

العربية فارسی

فارسی

SUPORTADO POR REDE

SUPORTADO POR REDE