Revolucionando o processamento de nozes: o poder das máquinas de classificação de cores do pistache

Mar 12, 2025

No mundo competitivo do processamento, a qualidade e a eficiência do Nut são fundamentais. Entre as muitas inovações que transformam a indústria, Máquinas de classificação de cores de pistache emergiram como um divisor de águas. Esses sistemas avançados garantem a qualidade consistente do produto, reduzem o desperdício e otimizam operações para produtores em todo o mundo. Vamos explorar como essa tecnologia funciona e por que é indispensável para o processamento moderno de pistache.

O desafio: entregando pistache impecável

Pistachos, com seus vibrantes grãos verdes e conchas cremosas, são um lanche amado. No entanto, sua jornada de pomar para consumidor está repleta de desafios. Variações naturais de cor, defeitos, fragmentos de concha ou materiais estranhos podem comprometer a qualidade do produto. A classificação manual tradicional é muito trabalhosa, demorada e propensa a erros humanos. À medida que a demanda global por pistache premium cresce, os processadores precisam de uma solução mais inteligente.

Como funcionam os classificadores de cores do pistache

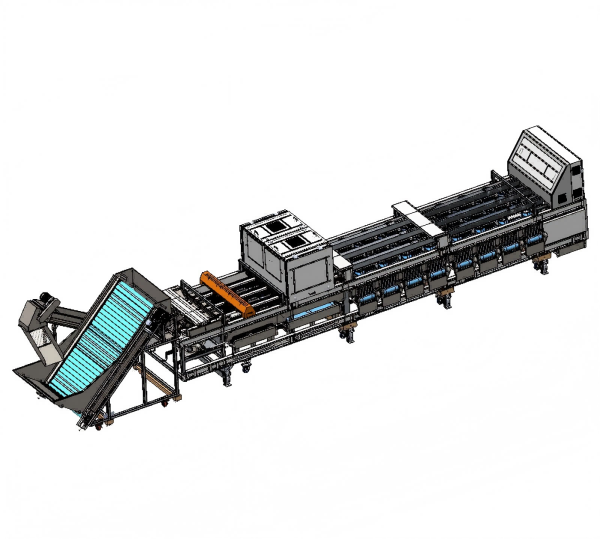

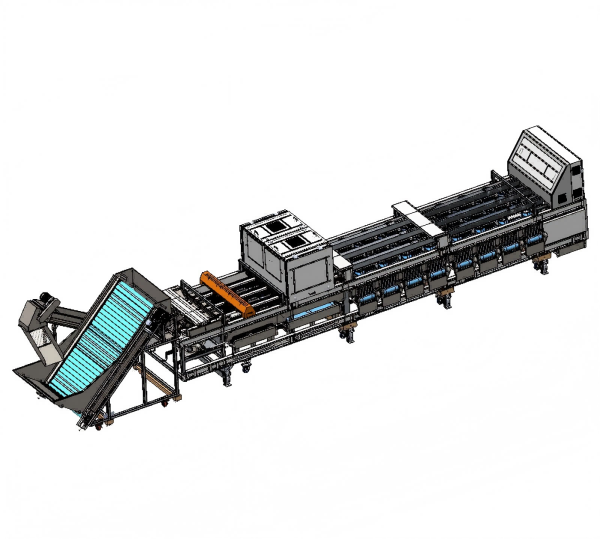

As máquinas de classificação de cores de pistache aproveitam a tecnologia óptica de ponta e a IA para inspecionar e separar nozes com precisão incomparável. Aqui está um detalhamento do processo:

-

Alimentação em alta velocidade: As nozes são alimentadas em uma rampa vibratória ou correia transportadora, garantindo uma distribuição uniforme.

-

Varredura óptica: Câmeras e sensores de alta resolução capturam imagens detalhadas de cada pistache. Uso de sistemas avançados Imagem multi-espectral (luz visível, infravermelha próxima) para detectar variações de cores, defeitos ou contaminantes invisíveis ao olho humano.

-

Análise de IA: Algoritmos de aprendizado de máquina analisam os dados em tempo real, comparando cada porca com parâmetros de qualidade predefinidos (por exemplo, intervalos de cores aceitáveis, integridade da concha).

-

Ejeção de precisão: As porcas defeituosas ou fora da cor são rapidamente removidas usando jatos de ar direcionados, garantindo que apenas pistache de grau premium prosseguissem para a embalagem.

-

Principais benefícios da tecnologia de classificação de cores

-

Controle de qualidade aprimorado

-

Detecta e remove grãos descoloridos, mofados ou danificados.

-

Identifica fragmentos de concha, pedras ou materiais estrangeiros.

-

Garante cor e aparência uniformes para marca premium.

-

Eficiência aumentada

-

Processa milhares de quilos por hora, superando muito o trabalho manual.

-

Reduz a dependência dos trabalhadores sazonais e minimiza os custos de mão -de -obra.

-

Redução de resíduos

-

Recupera nozes comestíveis que, de outra forma, poderiam ser descartadas devido a pequenos defeitos.

-

Reduz os custos de produção, maximizando o rendimento.

-

Conformidade com a segurança alimentar

-

Elimina contaminantes como nozes infectadas pela aflatoxina, atendendo a rigorosos padrões globais de segurança.

-

Por que os processadores de pistache não podem se dar ao luxo de ignorar esta tecnologia

O mercado global de pistache está crescendo, impulsionado pelo aumento do consumo consciente da saúde e pela demanda por nozes para lanches. Para permanecer competitivo, os processadores devem adotar tecnologias que garantam consistência e escalabilidade. Os classificadores de cores não apenas protegem a reputação da marca, mas também abrem portas para mercados premium, onde os consumidores esperam perfeição.

Além disso, as máquinas modernas são personalizáveis. Por exemplo, os processadores podem ajustar as configurações de sensibilidade para priorizar defeitos específicos (por exemplo, manchas escuras, divisões de concha) com base em preferências regionais ou requisitos do cliente.

-

O futuro da classificação de nozes

As inovações em IA e IoT estão levando a classificação de cores para o próximo nível. Alguns sistemas agora se integram algoritmos de auto-aprendizado Isso melhora a precisão ao longo do tempo, enquanto a conectividade em nuvem permite o monitoramento remoto e a análise de dados. À medida que a sustentabilidade se torna uma prioridade, essas máquinas também contribuem para reduzir o desperdício de alimentos-uma vantagem crítica em um mercado ecológico.

-

Conclusão

As máquinas de classificação de cores de pistache não são mais um luxo, mas uma necessidade para os processadores de nozes que visam prosperar em uma indústria orientada para a qualidade. Ao combinar velocidade, precisão e adaptabilidade, essa tecnologia garante que cada saco de pistache atenda aos mais altos padrões de paladar, segurança e apelo visual.

Para os processadores prontos para elevar suas operações, investir em um classificador de cores de última geração não é apenas inteligente-é essencial.

CN

CN português

português English

English français

français русский

русский español

español ไทย

ไทย Indonesia

Indonesia Tiếng việt

Tiếng việt العربية

العربية فارسی

فارسی

SUPORTADO POR REDE

SUPORTADO POR REDE